Electric Motor Repair Blog

Electric Motor Storage Checklist

While it’s never a good time for an electric motor to fail, there are several steps you can take to minimize the downtime and potential loss of revenue. The first is following the manufacturer’s regular maintenance and inspection recommendations to maximize the...

The Essential Guide to Getting Your Electric Motors Serviced and Repaired

Electric motors are essential to almost every industrial business. When a motor goes down, you must have the repairs done correctly and as soon as possible to minimize the financial impact on your business. This leaves owners and managers with two service or repair...

Eliminating Electric Motor Downtime

Because it’s never a good time for an electric motor failure, preventing unexpected downtime and cost is a primary concern for every maintenance and production manager. It’s no secret that taking care of your electric motors through preventative maintenance and proper...

Overview of Electric Motor Bearing Types and Applications

Industry relies on electric motors to keep assembly, production, and packaging lines moving. While motors vary by shape, size, and output, they all have two universal needs to operate: bearings and lubrication. As part of our commitment to keep you up and running,...

Best Electric Motor Repair Practices

Knowing the best electric motor repair practices can help reduce potential breakdowns and resulting downtime to keep your production up and running. Having a trusted expert on speed dial (800-713-0103) for when repairs exceed your available resources is equally...

Basic Electric Motor Testing Tools

Finding out what went wrong when your electric motor fails can help get you back online sooner rather than later. Unfortunately, determining the cause can be challenging without access to the proper testing tools and standards. So, to help you assemble your electric...

The Five Most Common Causes of Electric Motor Failure

Electric motors are essential for countless companies across hundreds of different industries. While production shutdowns for routine maintenance can be scheduled to minimize downtime and lost productivity, unexpected electric motor repairs or replacements can bring...

How Proper Repairs Impact Motor Efficiency and Longevity

It’s no secret that regular maintenance can prolong the lifespan of any electric motor. But when it’s time for repairs, many still believe that rewinding an electric motor will decrease efficiency between 1% and 5%. The basis for this misconception can be traced to...

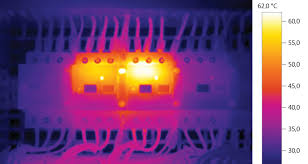

The Benefits of Infrared Thermography for Industrial Applications

What is Infrared Thermography? Infrared thermography can help your business minimize downtime, avoid costly repairs and improve safety. Infrared thermography is crucial for both condition-monitoring tasks and predictive maintenance plans. This non-destructive testing...

Lubrication for Electric Motors and Rotating Equipment

While it's evident that every electric motor or rotating equipment requires regular lubrication to operate efficiently, not all lubricants and lubrication systems are equal. For example, simple grease lubrication may suffice in some cases, while other situations...